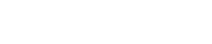

Heatless Modular Adsorption Air Dryer (Tbc)

Capacity range : 3~500 m3/min

Pressure range : 0.4~1.0MPa (4~10barg)

Max. inlet temperature : 43 ℃

Max. ambient temperature : 45 ℃

Power supply : 220V/1Ph/50Hz

PDP : -20 ℃ , -40 ℃ , -70 ℃

Rated condition :

Working pressure : 0.7Mpa

Inlet temperature : 38 ℃

Ambient temperature : 38 ℃

PDP : -20 ℃

Other :

Regeneration air consumption < 7%

Reliable Design

Supportive Ceramic Balls used at the bottom of adsorption tower make uniform air-flow distribution , in this way ,desiccant can be protected from soaking and also get longer service life , together with special designed stainless steel flow divider , pressure loss can be greatly reduced.

Special designed high performance desiccant can get best dew point.

A full range of standard configuration for high performance pneumatic valve, when it's running, reliability and pressure loss are significantly better than the film valve, solenoid valve.

Configuring multiple protection of electric heater, greatly improving the reliability. Standard gas control valve control

with high efficiency oil, dust filter.

Various control options

Standard configuration is using reliable PLC controller.

Optional Siemens and ABB brand PLC or touch screen and etc.

We can meet various customer requirements for communication, connecting RS485 I/O , Profibus or Modbus to Ethernet.

Energy-saving

LDCS-Load Dependent Control System ensure the case that performance is best and at the meantime to control the purge air loss accurately , compared with fixed cycle time control type ,LDCS could save at least 8% comprehensive energy consumption.

DPOS-Dew Point Operation System can delay adsorption time under unstable load, DPOS could save at least 75% comprehensive energy consumption.

(LDCS: Load Dependent Control System)

(DPOS: Dew Point Operation System)

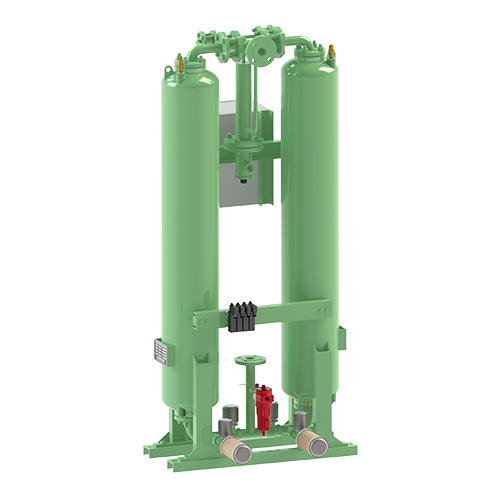

Technical Specification of RSXJ-10~RSXJ-5000 Series Heated Regeneration Compressed Air Dryer

| Model | Rated Flow | Electrical Supply | Nominal Power | Air Connections | Dimensions in mm | Weight | Filter (recommend the eligibility accessories) | |||

| RSXJ | (m3/min) | V/PH/Hz | Kw | mm | L | W | H | kg | Front | Postposition |

| RSXJ-30 | 3.0 | 380V/3PH/50HZ | 0.9 | DN25 | 800 | 400 | 1700 | 360 | O-0058G,A-0058G | R-0058G |

| RSXJ-60 | 6.0 | 380V/3PH/50HZ | 1.8 | DN40 | 1100 | 600 | 1950 | 600 | O-0125G,A-0125G | R-0125G |

| RSXJ-80 | 8.0 | 380V/3PH/50HZ | 2.4 | DN50 | 1100 | 600 | 2000 | 850 | O-0145G,A-0145G | R-0145G |

| RSXJ-100 | 10.0 | 380V/3PH/50HZ | 3.0 | DN50 | 1200 | 650 | 2000 | 950 | O-0220G/F,A-0220G/F | R-0220G/F |

| RSXJ-120 | 12.0 | 380V/3PH/50HZ | 3.6 | DN65 | 1200 | 650 | 2120 | 1000 | O-0220G/F,A-0220G/F | R-0220G/F |

| RSXJ-150 | 15.0 | 380V/3PH/50HZ | 4.5 | DN65 | 1300 | 700 | 2200 | 1150 | O-0330G/F,A-0330G/F | R-0330G/F |

| RSXJ-200 | 20.0 | 380V/3PH/50HZ | 6.0 | DN65 | 1400 | 720 | 2100 | 1400 | O-0430G/F,A-0430G/F | R-0430G/F |

| RSXJ-250 | 25.0 | 380V/3PH/50HZ | 7.5 | DN80 | 1400 | 720 | 2400 | 1750 | O-0430G/F,A-0430G/F | R-0430G/F |

| RSXJ-300 | 30.0 | 380V/3PH/50HZ | 9.0 | DN80 | 1700 | 760 | 2500 | 2000 | O-0620G/F,A-0620G/F | R-0620G/F |

| RSXJ-400 | 40.0 | 380V/3PH/50HZ | 12.0 | DN80 | 1750 | 840 | 2650 | 2450 | O-0620G/F,A-0620G/F | R-0620G/F |

| RSXJ-600 | 60.0 | 380V/3PH/50HZ | 18.0 | DN125 | 1900 | 1000 | 2780 | 3700 | O-1000F,A-1000F | R-1000F |

| RSXJ-800 | 80.0 | 380V/3PH/50HZ | 24.0 | DN150 | 2200 | 1200 | 2850 | 4500 | O-1300F,A-1300F | R-1300F |

| RSXJ-1000 | 100.0 | 380V/3PH/50HZ | 30.0 | DN150 | 2600 | 1500 | 3020 | 5000 | O-1950F,A-1950F | R-1950F |

| RSXJ-1200 | 120.0 | 380V/3PH/50HZ | 36.0 | DN150 | 2800 | 1600 | 3100 | 5500 | O-1950F,A-1950F | R-1950F |

| RSXJ-1500 | 150.0 | 380V/3PH/50HZ | 45.0 | DN200 | 3000 | 1600 | 3200 | 6000 | O-3250F,A-3250F | R-3250F |

| RSXJ-2000 | 200.0 | 380V/3PH/50HZ | 60.0 | DN200 |

for more details, PLS contact Risheng |

O-3250F,A-3250F | R-3250F | |||

| RSXJ-2500 | 250.0 | 380V/3PH/50HZ | 75.0 | DN200 | O-4650F,A-4650F | R-4650F | ||||

| RSXJ-3000 | 300.0 | 380V/3PH/50HZ | 90.0 | DN250 | O-5200F,A-5200F | R-5200F | ||||

| RSXJ-3500 | 350.0 | 380V/3PH/50HZ | 105.0 | DN300 | O-5850F,A-5850F | R-5850F | ||||

| RSXJ-4000 | 400.0 | 380V/3PH/50HZ | 120.0 | DN300 | O-6680F,A-6680F | R-6680F | ||||

| RSXJ-5000 | 500.0 | 380V/3PH/50HZ | 150.0 | DN350 | O-7800F,A-7800F | R-7800F | ||||

Features

Features

Specifications

Specifications