[Major Case Study] $150K Investment, $75K Annual Savings! How This Manufacturer Cut Electricity Costs in Half with Dryer Upgrades

Release time:2025-09-23

Compressed Air Dryer Upgrade: Slash Energy Costs by 40%+ and Boost Production Efficiency

In industrial operations, compressed air systems are notorious energy consumers. Legacy adsorption dryers compound this challenge with excessive air consumption, unstable dew points, and downstream pressure fluctuations—all adding up to crushing operational costs for manufacturers.

I. Critical Pain Points — Is Your Plant Still Paying for These Issues?

1. Excessive Air Consumption Traditional adsorption dryers consume 10%-14% of compressed air during regeneration. For a 40m³/min system, this translates to hundreds of thousands in wasted electricity costs annually!

2. Unstable Dew Point Performance Aging desiccants and temperature control issues cause dew point fluctuations that threaten process stability in precision manufacturing.

3. Energy Cost Drain Legacy equipment with high electrical heating loads and no heat recovery sends your electricity meter spinning like a turbine.

4. Pressure Instability High system pressure drops cause downstream equipment to cycle erratically, resulting in plummeting yield rates.

II. Four Revolutionary Technologies Transform Dryer Performance

1. Zero Purge Air Design | End Compressed Air Waste

· Core Technology: Blower-assisted ambient air regeneration completely eliminates parasitic air consumption

· Proven Results: One optoelectronics manufacturer upgraded 7 units, reducing compressor electricity costs by $879,800 annually—over 41% comprehensive energy savings!

2. Intelligent Dew Point Control | Performance Enhancement

· Dynamic Optimization: Dew point sensors plus AI algorithms optimize adsorption cycles in real-time. One automotive client extended switching cycles to 12 hours post-upgrade!

· Advanced Materials: Custom high-performance composite adsorbents deliver superior static/dynamic capacity with 30%+ longer service life.

3. Waste Heat Recovery System | Turn Waste into Gold

· Heat Source Revolution: Recover 110°C compressor waste heat for regeneration, cutting electrical consumption by 70%!

· Smart Load Management: Intelligent controls automatically leverage off-peak electricity rates, with nighttime heating saving tens of thousands per unit annually.

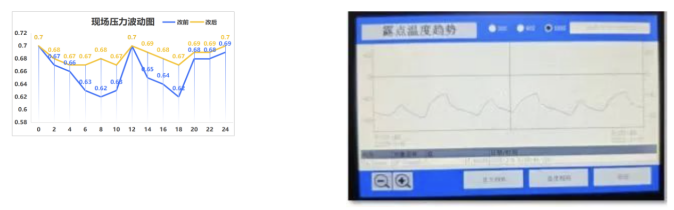

4. Integrated System Control | Rock-Solid Pressure Stability

· Low-Resistance Design: Optimized tower flow paths reduce pressure drop by 30%, maintaining steady downstream pressure

· Central Intelligence: PLC systems intelligently adjust loads, eliminating oversized equipment inefficiencies

III. Upgrade Benefits — Energy Savings Are Just the Beginning

1. Reduced Maintenance Costs New equipment extends adsorbent replacement intervals with 30%+ longer service life.

2. Lower Quality Risk More reliable, stable dew points dramatically reduce defect rates from moisture-related issues.

3. Reduced Carbon Footprint Heat recovery technology can eliminate hundreds of tons of CO₂ emissions annually, supporting corporate sustainability goals.

IV. Customer Testimonials — The Numbers Don't Lie

1. Aluminum Smelter, South China (One-Year Payback!) Upgraded to compression heat & blower combination zero-purge dryers, improving pressure dew point performance from -20°C to -40°C, saving 600 kWh daily per unit.

2. Electronics & Communications Manufacturer, East China Utilizing on-site chilled water cooling and custom adsorbents achieved stable -70°C pressure dew point with 35%+ average energy savings.

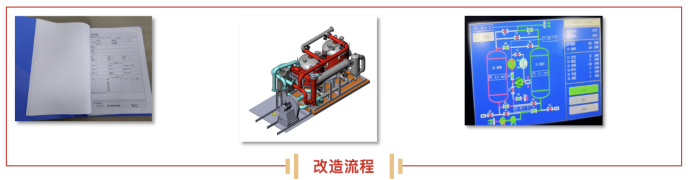

V. Four-Step Streamlined Upgrade Process for Rapid Results

Renovation Process

1. Free Assessment On-site engineers measure air consumption and dew point curves (48-hour report delivery).

2. Precision Selection Custom zero-purge blower heat/compression heat solutions (optimized for peak/off-peak electricity rates).

3. 30-Day Delivery Professional service team with 30+ years of technical expertise ensures guaranteed installation and commissioning.

4. Performance Verification Energy monitoring platform integration provides clear visibility into electricity savings.

Dryer upgrades represent more than equipment modernization—they're a critical step toward sustainable manufacturing. Through technological innovation and system optimization, we've helped numerous enterprises achieve 40%+ energy reductions with annual cost savings exceeding $1 million. Take action now and maximize every cubic meter of compressed air!

Unity | Collaboration | Progress

- END -

Source: After-Sales Service Department

Editor: Administration Department