压力传感器

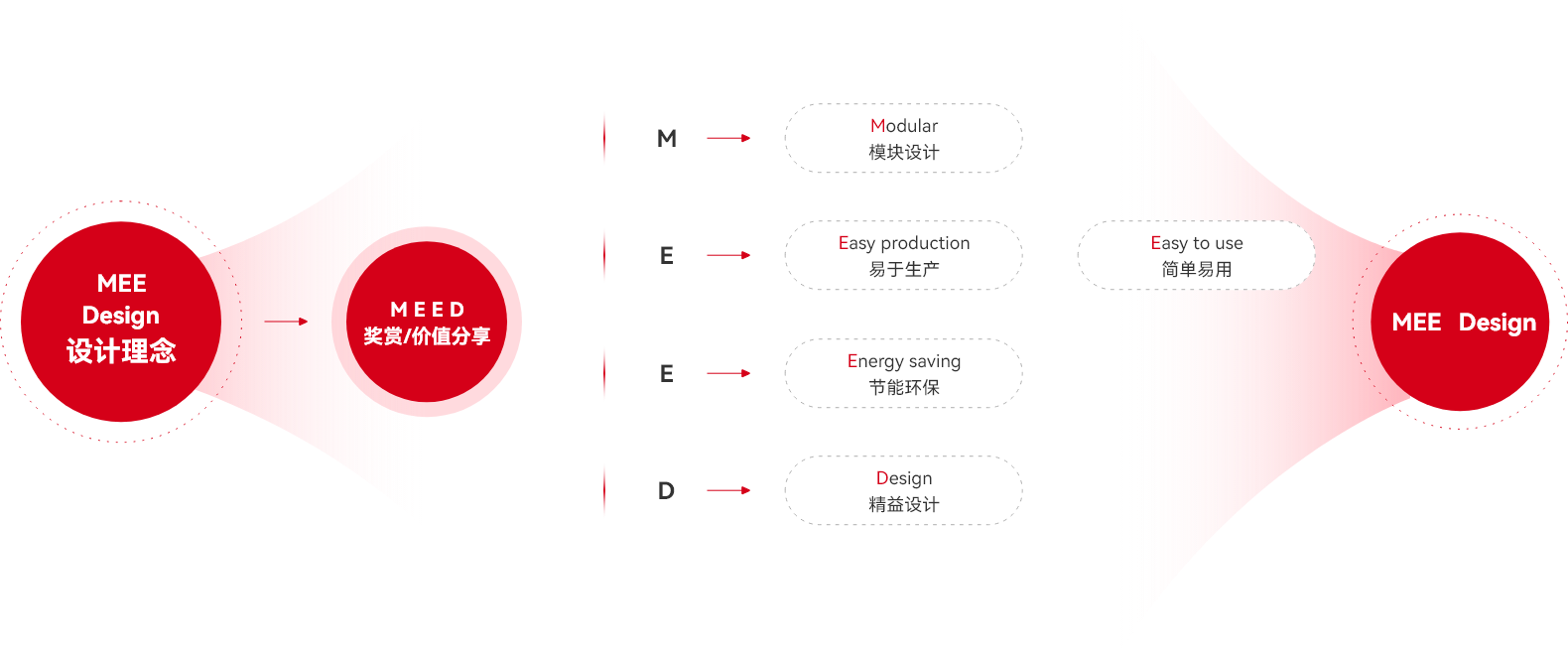

设计理念

以提供符合品质要求的压缩空气为前提,降低设备使用周期内用户的综合成本为原则。

研发能力

先进的手段,完善的设施,高效的流程

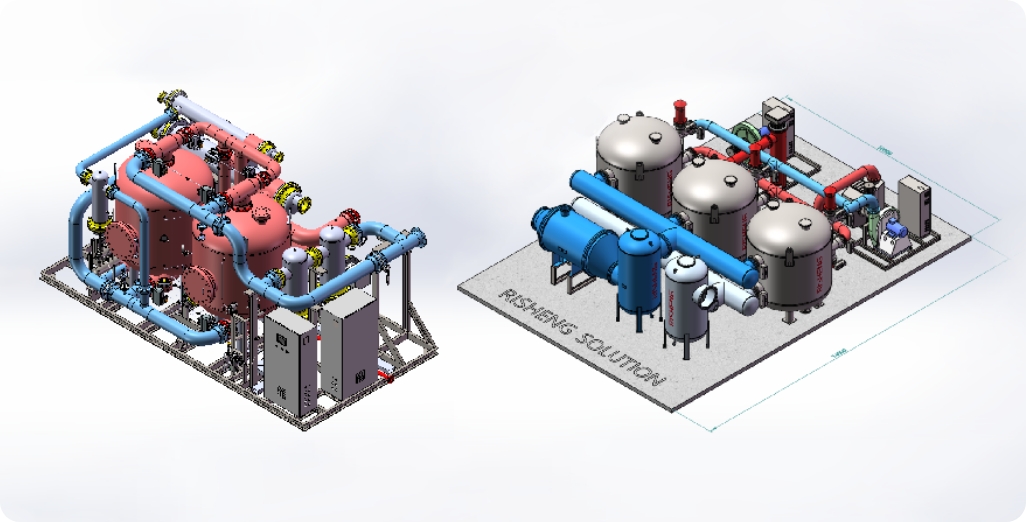

Solidworks 3D &PDM三维协同设计与数据管理

3D数字样机及产品设计数据管理

吸附增值模块设计与动态测试

换热器仿真设计与动态过程控制

吸附材料评价与开发

干燥机性能测试平台

阀门可靠性试验平台

多用途试验气派系统

压缩空气质量测试系统

成果展示

实力见证,成果共享

成果展示

获得中国机械工业科学技术二等奖

获得中国机械工业科学技术二等奖

中国标准化研究所,合肥通用所牵头

成果展示

国家火炬计划

两化融合管理体系评定证书

高新技术企业

零气耗压缩热专利证书

压缩热再生压缩空气净化装置

鼓风零气耗干燥机

零气耗鼓风加热再生吸干机

数字化

想 客户所想 广 先进思路 用 科学手段 集 软硬兼施 系 绿色低碳

制造能力

标准化、通用化

占地面积10000平方,杭州总部生产基地

湖州长兴生产基地,具备全球行业内领先的定制化大型吸干机、管道过滤器、 高效换热器的配套能力

来料PMI检测

自动焊接中心

吸附剂来料检测 (杭州&长兴)

带尾气焚烧处理的现代化喷漆房