压力传感器

针对空压系统提供

专业节能服务

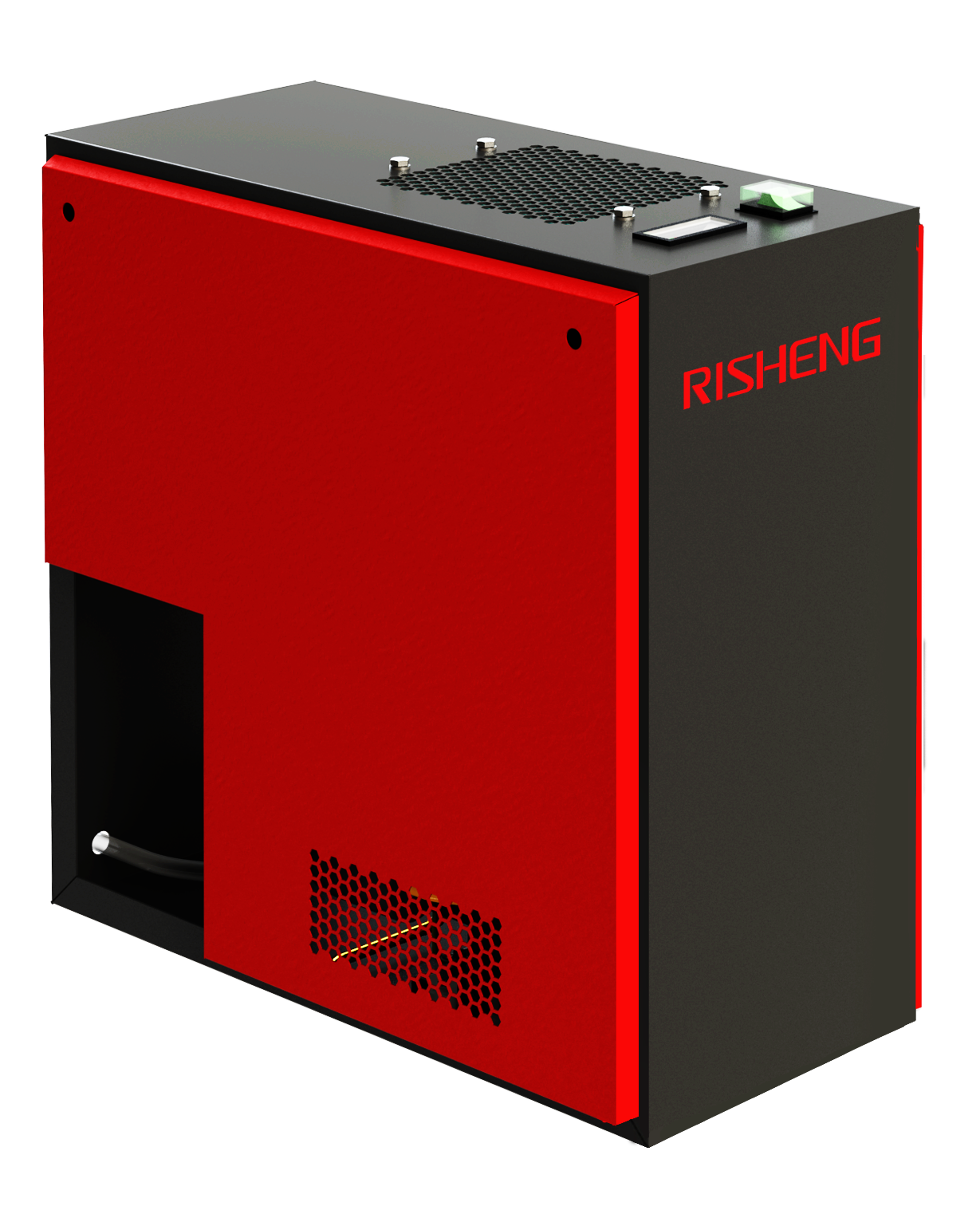

SSD系列冷冻式干燥器

PD 系列冷冻式空气干燥器

ST系列冷冻式干燥器

HT系列高温冷冻式空气干燥机

HP系列冷冻式空气干燥器

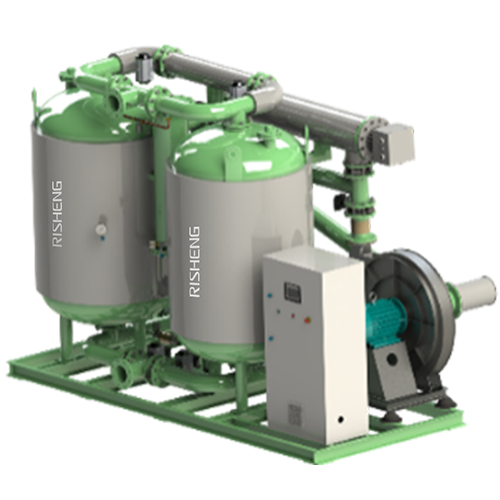

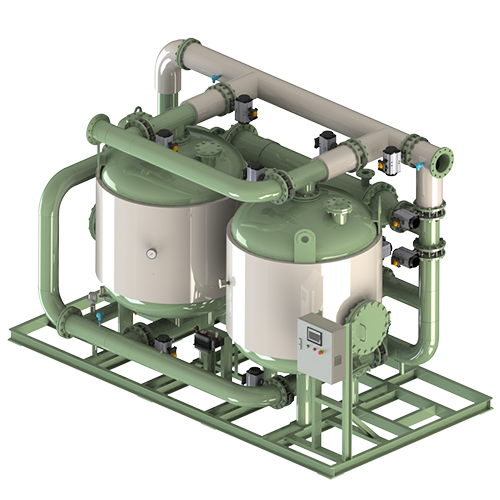

RSXB-ZP系列 零气耗鼓风加热再生吸附式干燥器

RSXB系列 微气耗鼓风加热再生吸附式干燥器

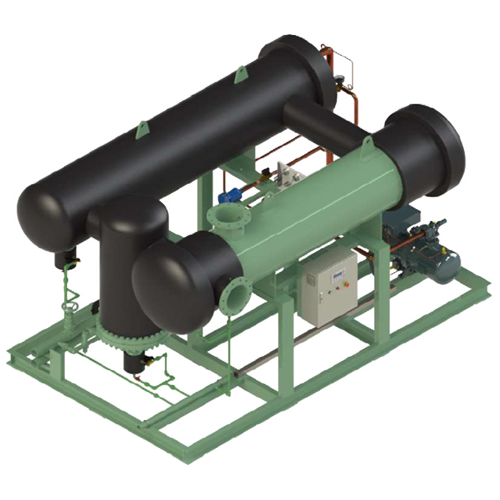

RSXY-ZP系列 零气耗压缩热再生吸附式干燥器

RSXY微气耗压缩热再生干燥器技术

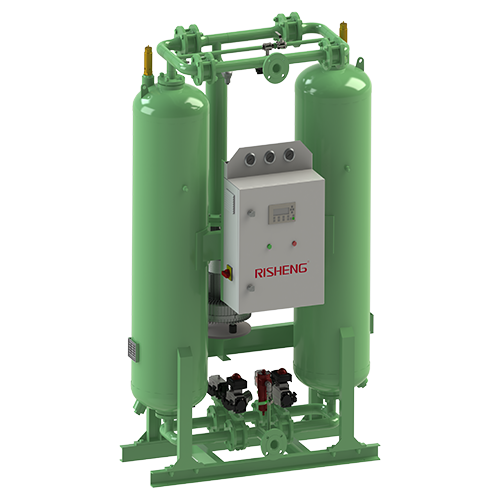

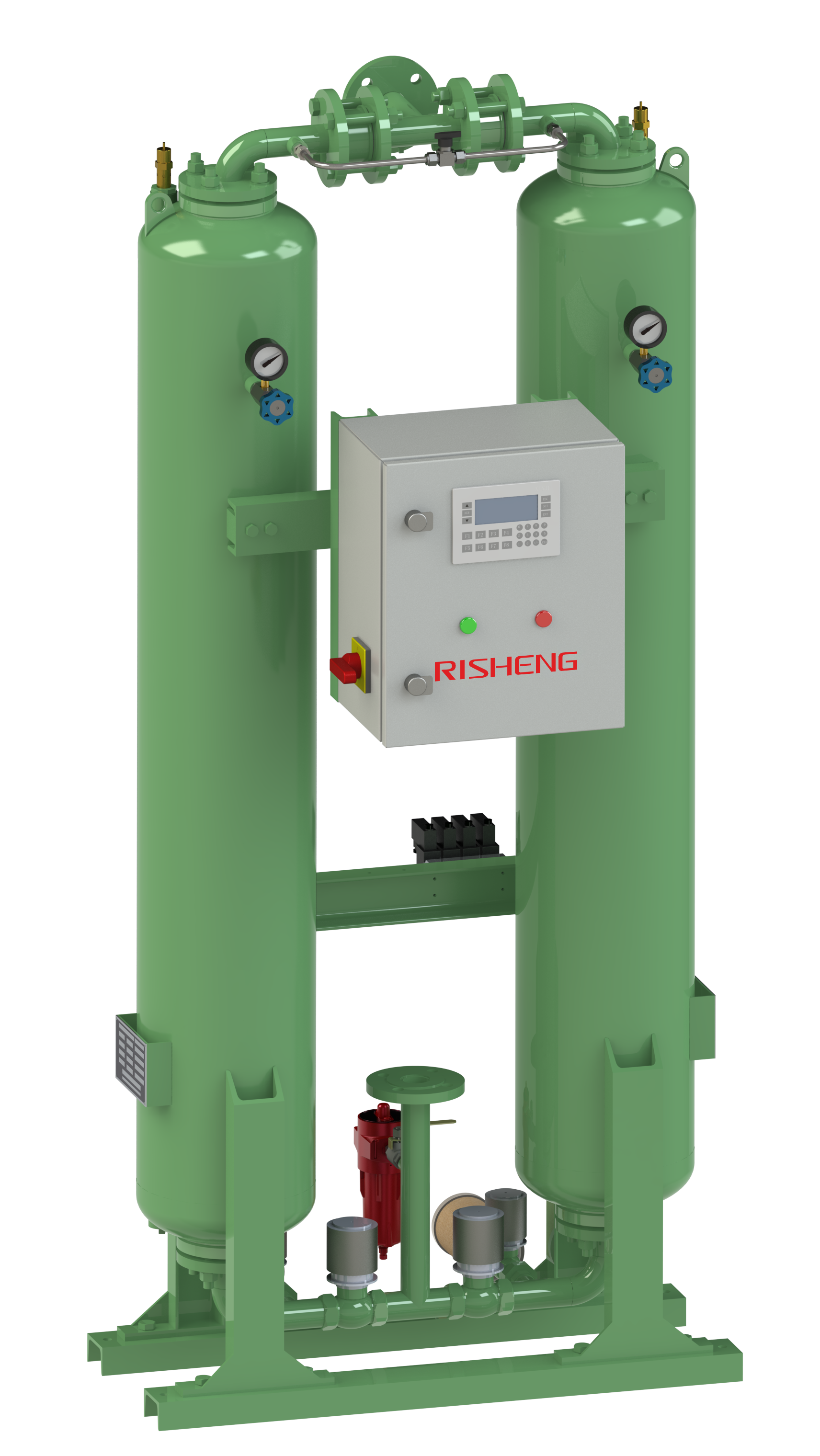

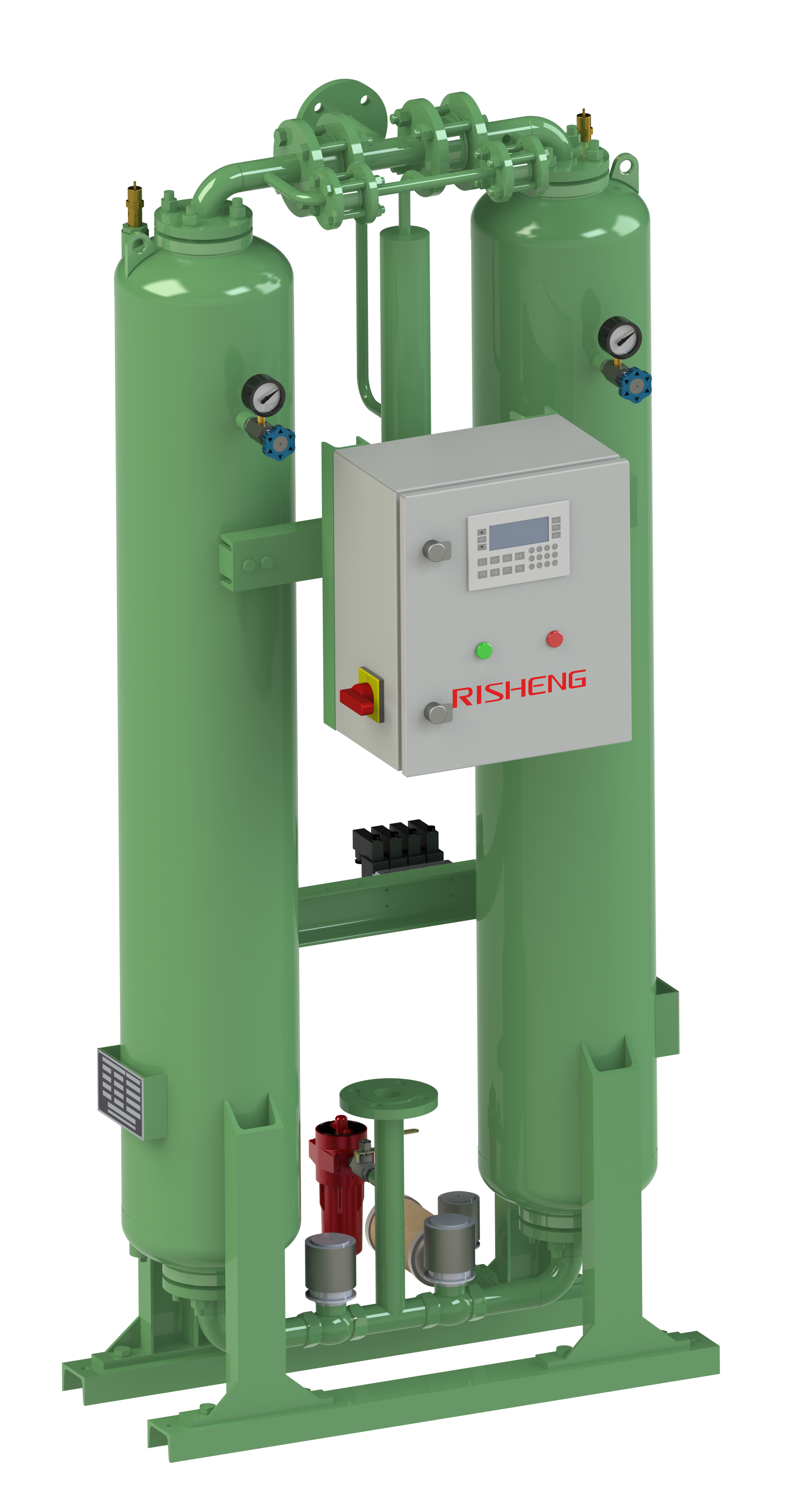

RSXW系列无热再生干燥器

RSXJ系列加热再生干燥器