压力传感器

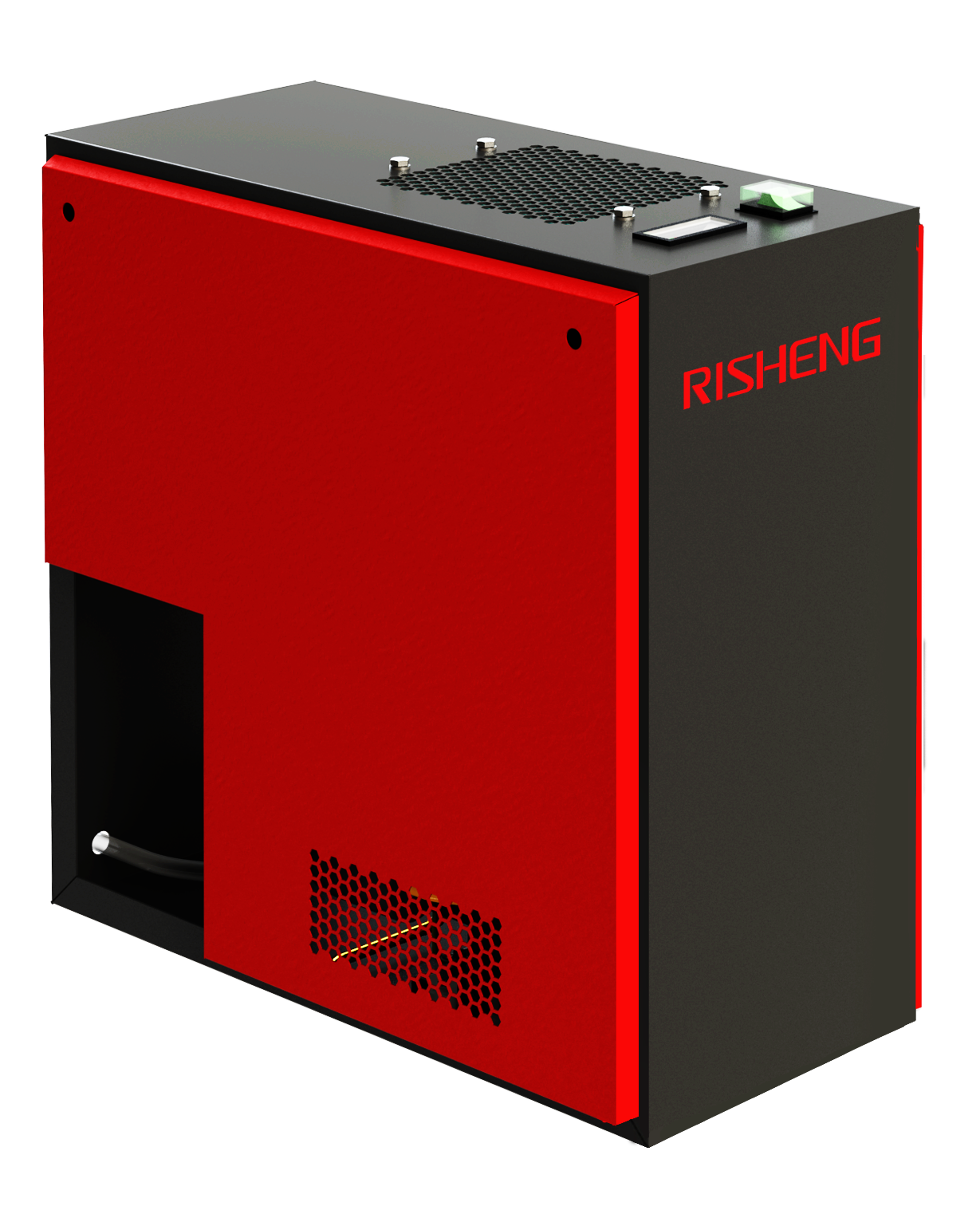

产品优势

坚固耐用

节能环保

安全可靠

多种控制选择

技术规格

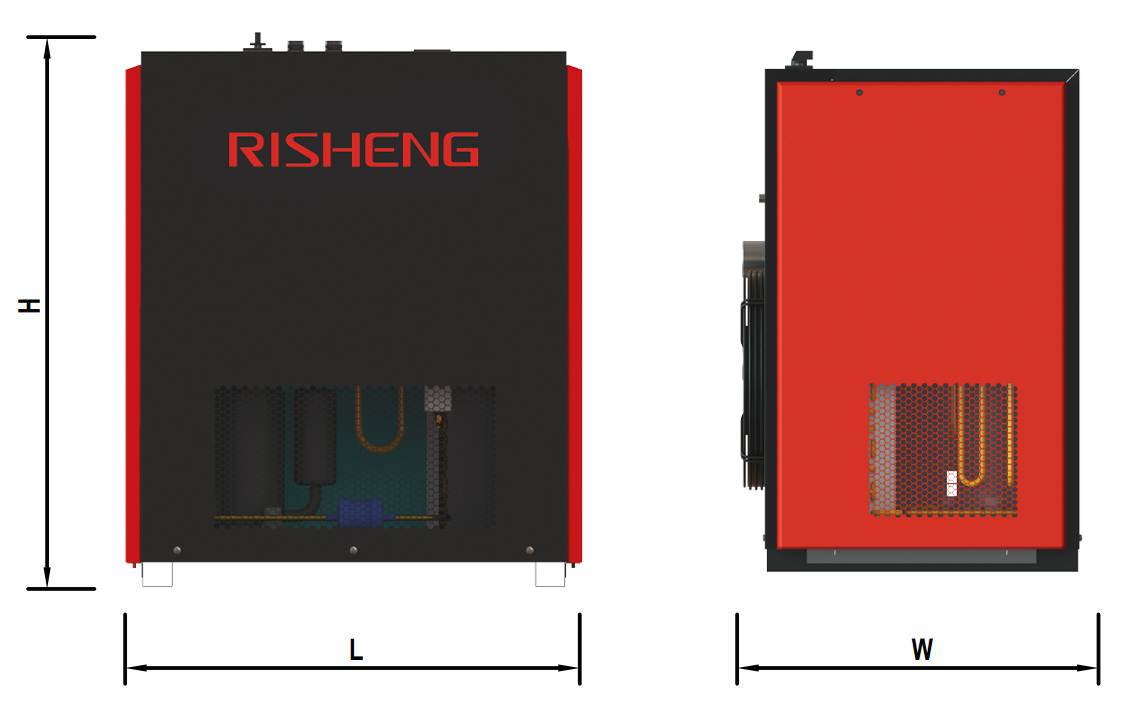

PD 系列风冷冷冻式干燥器技术参数

| 型号 | 处理量 | 口径 | 尺寸 | |||||||

| mm | inch | |||||||||

| m³/min | l/s | cfm | G / PN | 长 | 宽 | 高 | 长 | 宽 | 高 | |

| RSLF-60-PD | 6.5 | 109 | 230 | 1-1/2" M | 760 | 592 | 913 | 30 | 24 | 36 |

| RSLF-80-PD | 8.8 | 147 | 311 | 1-1/2" M | 760 | 592 | 913 | 30 | 24 | 36 |

| RSLF-100-PD | 11 | 184 | 389 | 1-1/2" M | 760 | 592 | 913 | 30 | 24 | 36 |

| RSLF-120-PD | 13 | 217 | 460 | 2" M | 1000 | 710 | 1030 | 40 | 28 | 41 |

| RSLF-150-PD | 17 | 284 | 601 | 2" M | 1000 | 710 | 1030 | 40 | 28 | 41 |

| RSLF-200-PD | 23 | 384 | 813 | 2" M | 1000 | 710 | 1030 | 40 | 28 | 41 |

| RSLF-250-PD | 27 | 450 | 954 | 2-1/2" M | 1000 | 830 | 1600 | 40 | 33 | 63 |

| RSLF-300-PD | 33 | 550 | 1166 | 2-1/2" M | 1000 | 830 | 1600 | 40 | 33 | 63 |

| RSLF-350-PD | 37 | 617 | 1307 | 2-1/2" M | 1000 | 830 | 1600 | 40 | 33 | 63 |

| RSLF-400-PD | 45 | 750 | 1589 | DN100 | 1250 | 1120 | 1750 | 50 | 45 | 69 |

| RSLF-500-PD | 55 | 917 | 1943 | DN100 | 1250 | 1120 | 1750 | 50 | 45 | 69 |

| RSLF-600-PD | 65 | 1084 | 2296 | DN100 | 1250 | 1120 | 1750 | 50 | 45 | 69 |

| RSLF-700-PD | 73 | 1217 | 2578 | DN125 | 1250 | 1120 | 1750 | 50 | 45 | 69 |

| RSLF-800-PD | 80 | 1334 | 2825 | DN150 | 1460 | 2000 | 1770 | 58 | 79 | 70 |

| RSLF-900-PD | 90 | 1500 | 3178 | DN150 | 1460 | 2000 | 1770 | 58 | 79 | 70 |

| RSLF-1000-PD | 100 | 1667 | 3531 | DN150 | 1460 | 2000 | 1770 | 58 | 79 | 70 |

| RSLF-1200-PD | 120 | 2000 | 4238 | DN150 | 1460 | 2000 | 1770 | 58 | 79 | 70 |

*额定进气压力7barg,进气温度38℃,环境温度38℃,压力露点3℃~10℃。其他电源可根据要求提供。

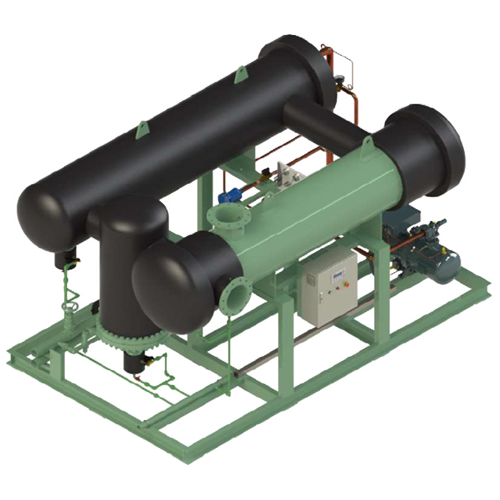

PD 系列水冷冷冻式干燥器技术参数

| 型号 | 处理量 | 口径 (空气) |

口径 (冷却水) |

尺寸 | |||||||

| mm | inch | ||||||||||

| m³/min | l/s | cfm | G / PN | G / PN | 长 | 宽 | 高 | 长 | 宽 | 高 | |

| RSLS-120-PD | 13 | 217 | 460 | 2" M | 3/4" M | 1000 | 710 | 1030 | 40 | 28 | 41 |

| RSLS-150-PD | 17 | 284 | 601 | 2" M | 3/4" M | 1000 | 710 | 1030 | 40 | 28 | 41 |

| RSLS-200-PD | 23 | 384 | 813 | 2" M | 3/4" M | 1000 | 710 | 1030 | 40 | 28 | 41 |

| RSLS-250-PD | 27 | 450 | 954 | 2-1/2" M | 1" M | 1000 | 830 | 1600 | 40 | 33 | 63 |

| RSLS-300-PD | 33 | 550 | 1166 | 2-1/2" M | 1" M | 1000 | 830 | 1600 | 40 | 33 | 63 |

| RSLS-350-PD | 37 | 617 | 1307 | 2-1/2" M | 1" M | 1000 | 830 | 1600 | 40 | 33 | 63 |

| RSLS-400-PD | 45 | 750 | 1589 | DN100 | 1-1/4" M | 1100 | 1010 | 1750 | 44 | 40 | 69 |

| RSLS-500-PD | 55 | 917 | 1943 | DN100 | 1-1/4" M | 1100 | 1010 | 1750 | 44 | 40 | 69 |

| RSLS-600-PD | 65 | 1084 | 2296 | DN100 | 1-1/4" M | 1100 | 1010 | 1750 | 44 | 40 | 69 |

| RSLS-700-PD | 73 | 1217 | 2578 | DN125 | 1-1/4" M | 1100 | 1010 | 1750 | 44 | 40 | 69 |

| RSLS-800-PD | 80 | 1334 | 2825 | DN150 | 1-1/2" M | 1100 | 1500 | 1800 | 44 | 60 | 71 |

| RSLS-900-PD | 90 | 1500 | 3178 | DN150 | 1-1/2" M | 1100 | 1500 | 1800 | 44 | 60 | 71 |

| RSLS-1000-PD | 100 | 1667 | 3531 | DN150 | 1-1/2" M | 1100 | 1770 | 1800 | 44 | 70 | 71 |

| RSLS-1200-PD | 120 | 2000 | 4238 | DN150 | 1-1/2" M | 1100 | 1770 | 1800 | 44 | 70 | 71 |

| RSLS-1500-PD | 150 | 2500 | 5297 | DN200 | 1-1/2" M | 1225 | 2220 | 1800 | 49 | 88 | 71 |

| RSLS-1800-PD | 180 | 3000 | 6356 | DN200 | 1-1/2" M | 1225 | 2220 | 1800 | 49 | 88 | 71 |

*额定进气压力7barg,进气温度38℃,冷却水温度32℃,压力露点3℃~10℃。其他电源可根据要求提供。

校正因素

实际容量(m³/ min)=额定容量×KA×KB×KC

| 工作压力 (KA) | Mpag | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 0.9 |

| psig | 44 | 58 | 73 | 87 | 102 | 116 | 131 | |

| CFP | 0.76 | 0.86 | 0.92 | 0.93 | 1.00 | 1.04 | 1.08 | |

| Mpag | 1.0 | 1.1 | 1.2 | 1.3 | 1.4 | 1.5 | ||

| psig | 145 | 160 | 174 | 189 | 203 | 218 | ||

| CFP | 1.11 | 1.15 | 1.18 | 1.22 | 1.25 | 1.28 |

| 入口温度 (KB) | ℃ | 35 | 38 | 40 | 46 | 49 | 54 | 60 |

| ℉ | 95 | 100 | 104 | 115 | 120 | 129 | 140 | |

| CFT | 1.11 | 1.00 | 0.92 | 0.76 | 0.69 | 0.56 | 0.46 |

| 环境温度 (KC) | ℃ | 25 | 30 | 35 | 38 | 40 | 45 | 50 |

| ℉ | 77 | 86 | 95 | 100 | 104 | 113 | 122 | |

| CFT | 1.15 | 1.10 | 1.02 | 1.00 | 0.89 | 0.79 | 0.69 |

| 冷却水温度 (KC') | ℃ | 20 | 25 | 32 | 35 | 40 |

| ℉ | 68 | 77 | 90 | 95 | 104 | |

| CFT | 1.17 | 1.09 | 1.00 | 0.92 | 0.84 |

KC用于空气冷却

KC'用于水冷却

额定条件

工作范围

可用选项

其他产品

针对空压系统提供专业节能服务

SSD系列冷冻式干燥器

探索更多

ST系列冷冻式干燥器

探索更多

HT系列高温冷冻式空气干燥机

探索更多