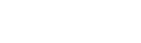

产品优势

节能特点显著

添加额外的加热装置 = 带加热器辅助装置

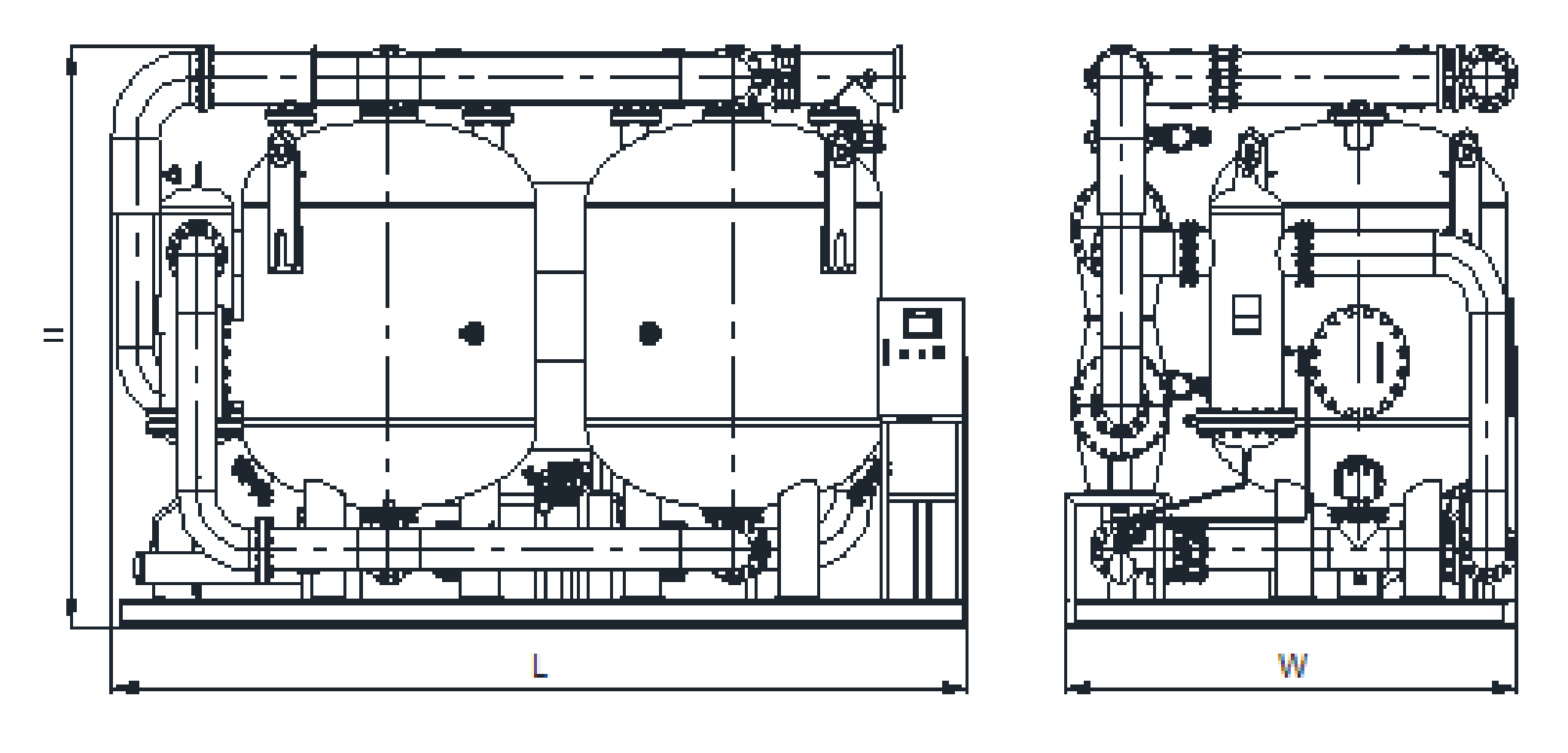

技术规格

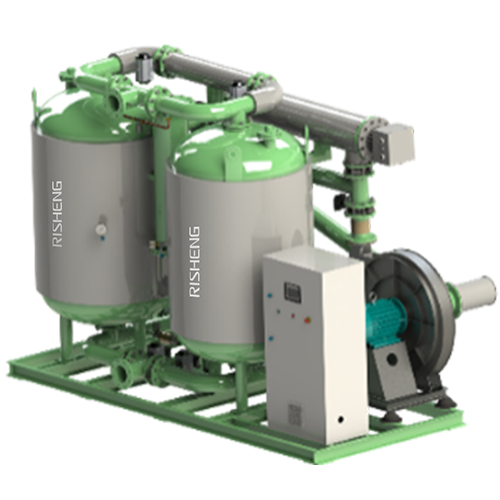

配备无油螺杆压缩机

| 型号 | 处理量 | 后置过滤器(推荐) | 口径 (空气) |

口径 (冷却水) |

尺寸 | |||||||

| mm | inch | |||||||||||

| Nm³/min | l/s | cfm | 1μm | G / PN | G / PN | 长 | 宽 | 高 | 长 | 宽 | 高 | |

| RSXY-100 | 10 | 167 | 354 | AO-060F | DN50 | DN65 | 2402 | 1211 | 2389 | 95 | 48 | 95 |

| RSXY-120 | 12 | 200 | 424 | AO-060F | DN50 | DN65 | 2402 | 1211 | 2389 | 95 | 48 | 95 |

| RSXY-150 | 15 | 250 | 530 | AO-070F | DN50 | DN65 | 2402 | 1211 | 2389 | 95 | 48 | 95 |

| RSXY-200 | 20 | 334 | 707 | AO-070F | DN65 | DN65 | 2451 | 1340 | 2598 | 97 | 53 | 103 |

| RSXY-220 | 22 | 367 | 777 | AO-080F | DN65 | DN65 | 2451 | 1340 | 2598 | 97 | 53 | 103 |

| RSXY-250 | 25 | 417 | 883 | AO-080F | DN65 | DN65 | 2451 | 1340 | 2598 | 97 | 53 | 103 |

| RSXY-350 | 35 | 584 | 1236 | AO-090F | DN80 | DN65 | 2882 | 1378 | 2605 | 114 | 55 | 103 |

| RSXY-450 | 45 | 750 | 1589 | AO-100F | DN100 | DN65 | 2899 | 1525 | 2717 | 115 | 61 | 107 |

| RSXY-500 | 50 | 834 | 1766 | AO-100F | DN100 | DN65 | 2899 | 1525 | 2717 | 115 | 61 | 107 |

| RSXY-600 | 60 | 1000 | 2119 | AO-100F | DN100 | DN65 | 3022 | 1568 | 2717 | 119 | 62 | 107 |

| RSXY-700 | 70 | 1167 | 2472 | AO-110F | DN125 | DN65 | 3710 | 1878 | 2813 | 147 | 74 | 111 |

| RSXY-800 | 80 | 1334 | 2825 | AO-110F | DN125 | DN65 | 3710 | 1878 | 2813 | 147 | 74 | 111 |

| RSXY-900 | 90 | 1500 | 3178 | AO-120F | DN150 | DN80 | 4160 | 2063 | 2975 | 164 | 82 | 118 |

| RSXY-1000 | 100 | 1667 | 3531 | AO-120F | DN150 | DN80 | 4160 | 2063 | 2975 | 164 | 82 | 118 |

| RSXY-1200 | 120 | 2000 | 4238 | AO-120F | DN150 | DN80 | 4160 | 2063 | 2975 | 164 | 82 | 118 |

| RSXY-1500 | 150 | 2500 | 5297 | AO-130F | DN200 | DN80 | 4800 | 2500 | 2909 | 189 | 99 | 115 |

| RSXY-1800 | 180 | 3000 | 6356 | AO-140F | DN200 | DN125 | 5400 | 2843 | 3409 | 213 | 112 | 135 |

| RSXY-2000 | 200 | 3334 | 7062 | AO-140F | DN200 | DN125 | 5400 | 2843 | 3409 | 213 | 112 | 135 |

| RSXY-2500 | 250 | 4167 | 8828 | AO-150F | DN200 | DN125 | 5400 | 2843 | 3409 | 213 | 112 | 135 |

*额定进气压力7barg,进气温度180℃~200℃,冷却水温度32℃,露点-40℃。

配备无油离心压缩机

| 型号 | 处理量 | 后置过滤器(推荐) | 口径 (空气) |

口径 (冷却水) |

尺寸 | |||||||

| mm | inch | |||||||||||

| Nm³/min | l/s | cfm | 1μm | G / PN | G / PN | 长 | 宽 | 高 | 长 | 宽 | 高 | |

| RSXY-100ZP | 10 | 167 | 354 | AO-060F | DN50 | DN65 | 2402 | 1118 | 2389 | 95 | 45 | 95 |

| RSXY-120ZP | 12 | 200 | 424 | AO-060F | DN50 | DN65 | 2402 | 1118 | 2389 | 95 | 45 | 95 |

| RSXY-150ZP | 15 | 250 | 530 | AO-070F | DN50 | DN65 | 2402 | 1118 | 2389 | 95 | 45 | 95 |

| RSXY-200ZP | 20 | 334 | 707 | AO-070F | DN65 | DN65 | 2454 | 1253 | 2598 | 97 | 50 | 103 |

| RSXY-220ZP | 22 | 367 | 777 | AO-080F | DN65 | DN65 | 2454 | 1253 | 2598 | 97 | 50 | 103 |

| RSXY-250ZP | 25 | 417 | 883 | AO-080F | DN65 | DN65 | 2454 | 1253 | 2598 | 97 | 50 | 103 |

| RSXY-350ZP | 35 | 584 | 1236 | AO-090F | DN80 | DN65 | 2932 | 1378 | 2605 | 116 | 55 | 103 |

| RSXY-450ZP | 45 | 750 | 1589 | AO-100F | DN100 | DN65 | 3048 | 1525 | 2717 | 120 | 61 | 107 |

| RSXY-500ZP | 50 | 834 | 1766 | AO-100F | DN100 | DN65 | 3048 | 1525 | 2717 | 120 | 61 | 107 |

| RSXY-600ZP | 60 | 1000 | 2119 | AO-100F | DN100 | DN65 | 3048 | 1568 | 2717 | 120 | 62 | 107 |

| RSXY-700ZP | 70 | 1167 | 2472 | AO-110F | DN125 | DN65 | 3710 | 1878 | 2813 | 147 | 74 | 111 |

| RSXY-800ZP | 80 | 1334 | 2825 | AO-110F | DN125 | DN65 | 3710 | 1878 | 2813 | 147 | 74 | 111 |

| RSXY-900ZP | 90 | 1500 | 3178 | AO-120F | DN150 | DN80 | 4190 | 2063 | 2975 | 165 | 82 | 118 |

| RSXY-1000ZP | 100 | 1667 | 3531 | AO-120F | DN150 | DN80 | 4190 | 2063 | 2975 | 165 | 82 | 118 |

| RSXY-1200ZP | 120 | 2000 | 4238 | AO-120F | DN150 | DN80 | 4190 | 2063 | 2975 | 165 | 82 | 118 |

| RSXY-1500ZP | 150 | 2500 | 5297 | AO-130F | DN200 | DN80 | 4821 | 2500 | 2909 | 190 | 99 | 115 |

| RSXY-1800ZP | 180 | 3000 | 6356 | AO-140F | DN200 | DN125 | 5468 | 2843 | 3409 | 216 | 112 | 135 |

| RSXY-2000ZP | 200 | 3334 | 7062 | AO-140F | DN200 | DN125 | 5468 | 2843 | 3409 | 216 | 112 | 135 |

| RSXY-2500ZP | 250 | 4167 | 8828 | AO-150F | DN200 | DN125 | 5468 | 2843 | 3409 | 216 | 112 | 135 |

*额定进气压力7barg,进气温度>110℃,冷却水温度32℃,露点-20℃。

RSXY系列压缩热再生干燥机选型修正

压力修正系数(KA)

| 5 barg | 6 barg | 7 barg | 8 barg | 9 barg | 10 barg |

| 0.75 | 0.87 | 1.00 | 1.13 | 1.25 | 1.38 |

进气温度修正系数(KB)

| 25℃ | 30℃ | 32℃ | 35℃ |

| 1.48 | 1.12 | 1.00 | 0.85 |

实际公称容积流量=选型流量×KA×KC'

如有较高的压力、流量等需求,欢迎咨询。

额定条件

工作范围

可用

其他产品

针对空压系统提供专业节能服务

RSXB-ZP系列 零气耗鼓风加热再生吸附式干燥器

探索更多

RSXB系列 微气耗鼓风加热再生吸附式干燥器

探索更多

RSXY微气耗压缩热再生干燥器技术

探索更多