如何给空压站房把个脉?

发布时间:2024-01-05

对于无论是设备厂商还是用户自身,要想了解一个空压站房现有的基本情况,借鉴中医核心的四个步骤就能很好的理解:

望

观察现有空压站设备使用情况

空压机

了解空压机类型——离心机、螺杆机(无油/喷油螺杆;工(定)频/变频;风/水冷)、涡旋机......

了解空压机核心参数——排气压力、温度;螺杆设备需关注加卸载时间;离心设备需关注电流、VSD开度、放空情况;

干燥机

干燥机类型,容器压力及年限、耗电、耗气情况(耗气往往是偏差最大的一项,要靠专业检测数据来评估而非铭牌上的名义排气量)等;

制氮机

制氮纯度,流量等;

过滤器

过滤精度,容器压力及年限;

储气罐

容器体积、耐温耐压及年限;

管路

管路布局及管径。

闻

了解用气工艺及需求

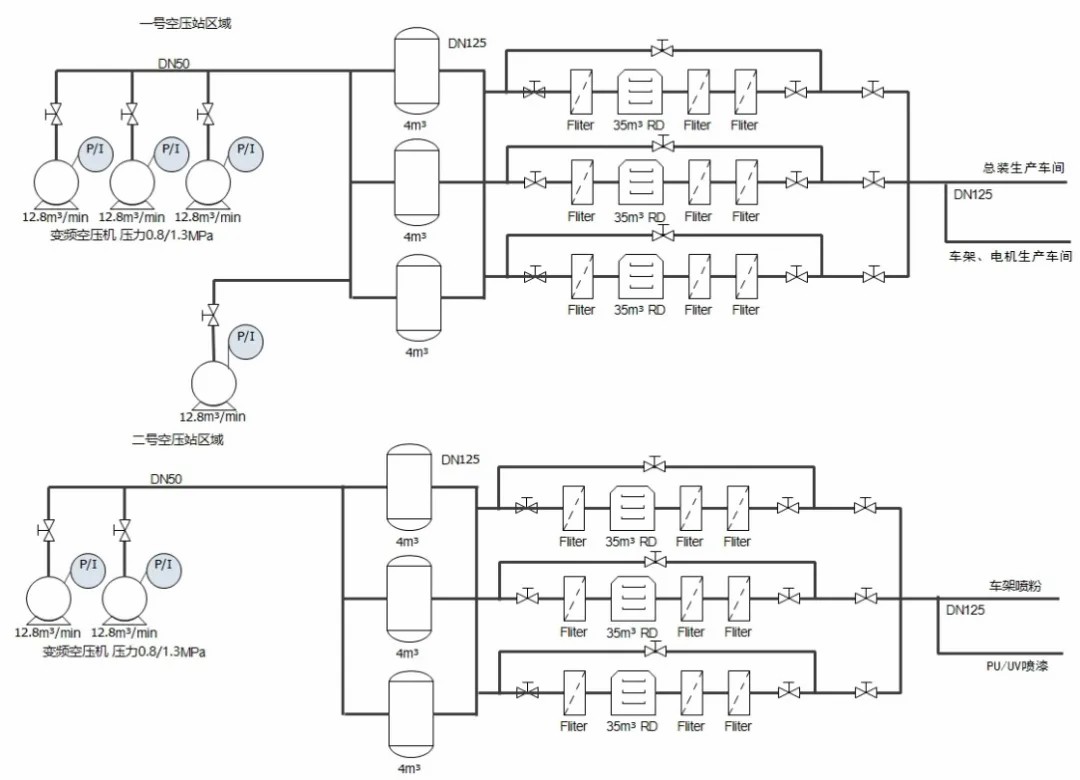

现场用气用于哪几部分工艺?如上图示意就有喷漆、喷粉、仪表、焊接等用气工艺;第二步摸底各工艺路线对于压缩空气的要求:如压力;水、尘、油含量;温度;材质;氮气纯度等等。

问

询问现有用气痛点,了解用气规律

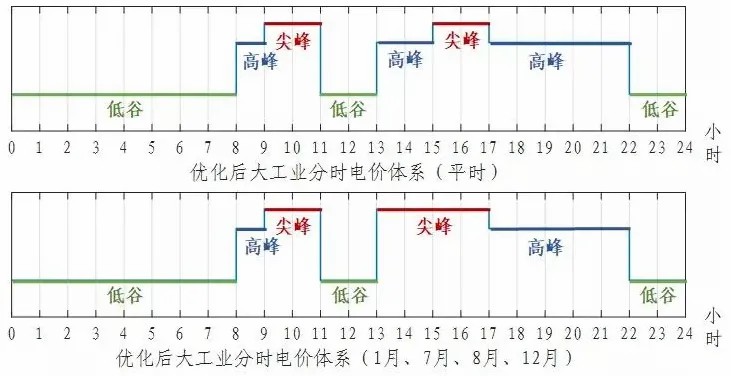

现有空压站配置在流量、压力、水油尘方面有什么困扰?比较常见的就是产能扩张,流量及压力捉襟见肘,但目前站房年用电量、年用气量如何?厂区平均电单价如何?厂区电费结算方式?峰谷电价格情况等。

现有空压站房的监管水平如何?

从低到高的发展大体可分为:就地控制——DCS集控——远程PC端实时监控——数字化孪生、智能化运维。

切

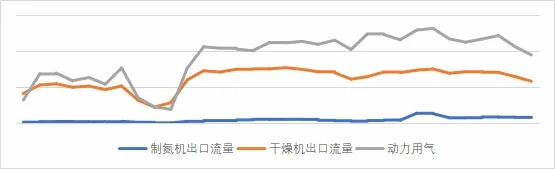

为现有站房气体品质及能效把脉

用电单耗(kW/(m³/min)):压缩空气站每输出单位容积压缩空气(空压机组吸气状态)所消耗的电量。根据用气类型还可以分成冷冻干燥压缩空气、吸附干燥压缩空气、氮气等不同工艺用气单独核算成本。

例如,现场有2台250kw工频空压机,现场配置有冷干机和微热吸干机,通过检测吸干机出口平均流量为55m³/min,空压站主设备平均运行能耗合计530kw,则站房用电单耗为530/55=9.64kw/( m³/min)。

在此基础上,结合现场电费平均单价,可以进一步核算出单位用电成本(元/m³)。

以电费平均单价0.8元/kWH为例,上一例空压站房合计9.64kw/(m³/min)×0.8元/kWH÷60min/H=0.13元/ m³。

我们还可以再考虑上保养、人工成本、设备十年折旧的支出,把这些支出平摊到每m³用气的成本中可以更准确的评估空压站房系统的支出情况和用气真实成本。

*以上为浙江省工业用电峰谷电价

(峰谷电价差大,削峰填谷很有必要)

其实更精细化的管理需要落实到尖峰、高峰、低谷的用电和不同电费结算单价来计算。我司运维型设备还能利用削峰填谷的控制手段,在节电最大化的情况下再做到谷电结费。

结语

现在行业内也在积极推动一级能效空压站房。

从设备制造厂家角度来看,对于一级能效空压站房我们非常欢迎。因为这是一个良币驱逐劣币的很好途径,干燥机又是其中的核心节能环节。

从运维角度来看,就会关注到一级能效空压站房可以反应出站房具备节能的硬件实力。但是,用户现场运行工况和需求是复杂多变的,而能效站房的评定只是对于空压站系统的耗电结合性能做短期监测后出具的定性评估。所以,必须配合系统的优化和用户使用习惯的匹配才能真正做到节能减排最大化。

结合在线的系统检测设备,让用户使用压缩空气像使用水、电、天然气一样简单纯粹才是我们应该为之努力的方向,也是现场空压站房精细化管理的出路。

日盛在运维领域,

也将利用自身优势同合作伙伴,

一起投身低碳事业,

助力节能减排。

团结 | 合作 | 共进

- END