日盛工业中试试验气源系统

发布时间:2023-12-14

该装置可以稳定无极调控流量,压力,温度,含水量等等参数的压缩空气。

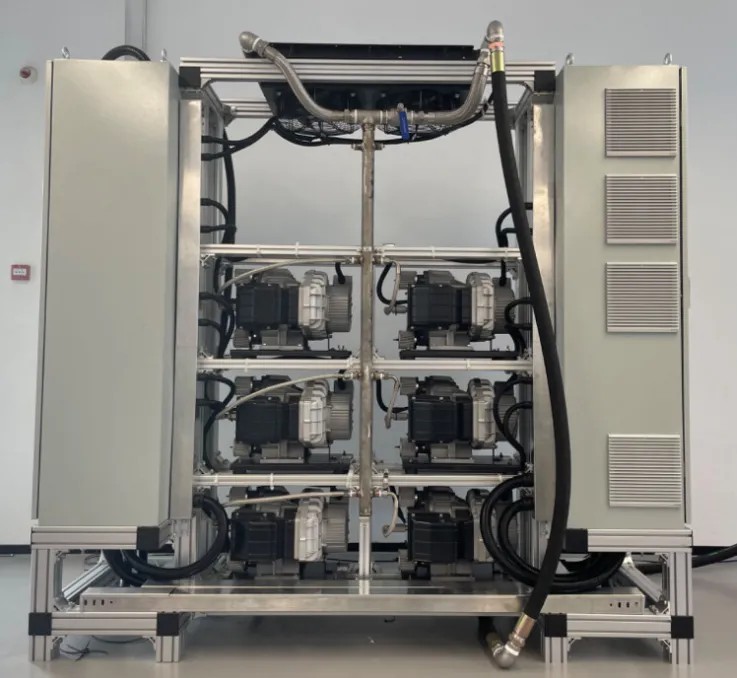

01 该装置 整体分成四个小模块

上图为装置一部分,其为模块化变频无油空压系统。该装置采用铝型材框架结构,配置多机头无油涡旋空压机,每个机头采用变频器一对一控制,集中控制器自动分配负荷,整体无油,体积小,噪音小,同时通过开关旁路阀可切换提供常温或者高温压缩空气。

该装置可独立运行,提供指定流量的压缩空气。

如上图所示从左至右分别是装置二三四。装置二为供气缓冲储气罐,装置三包括冷冻水调节系统,压缩空气管路调节阀,压缩空气排气缓冲罐以及中控系统等单元,装置四包括各种切换阀门,加热系统及干燥系统等单元。

整体分成四个小模块,每个模块承担不同的功能。

02 该装置 用于不同设备的测试

该装置配合环境温度调节等装置可分别用于不同设备的测试。

如10~60℃的湿饱和压缩空气适用于以下一些场景:

冷干机的常规负荷测试与极限过载测试(配合环境温度调节装置)

吸附剂的动态吸附曲线的模拟测定

无热/加热模块化吸干机的性能测试

鼓风加热再生吸干机的整机性能测试

30~200℃的极干燥压缩空气则可用于以下一些测试:

加热/鼓风加热干燥机的加热再生模拟测试

鼓风加热干燥机的吹冷再生模拟测试

无热干燥机的再生模拟测试

精密气动元件的冷/热疲劳测试

露点仪检测结果对比

含湿量可调的100~200℃的不饱和压缩空气可用于模拟高温空压机排气,广泛应用于测试过程中,比如:

压缩热再生吸附式干燥机的整机性能测试

压缩热再生吸附式干燥机的热再生模拟测试

风冷/水冷后部冷却器性能测试

油漆/橡胶/密封圈等零部件耐温性测试

阀门热负荷下疲劳测试

中试试验气源系统

总而言之,该装置解决了设备研发过程中需要实测涉及的各种压缩空气要求,为日盛的研发测试工作提供了绝佳的硬件条件。

团结 | 合作 | 共进

- END