吸附式压缩空气干燥机在钢铁行业的应用

发布时间:2023-10-25

01/压缩空气的使用

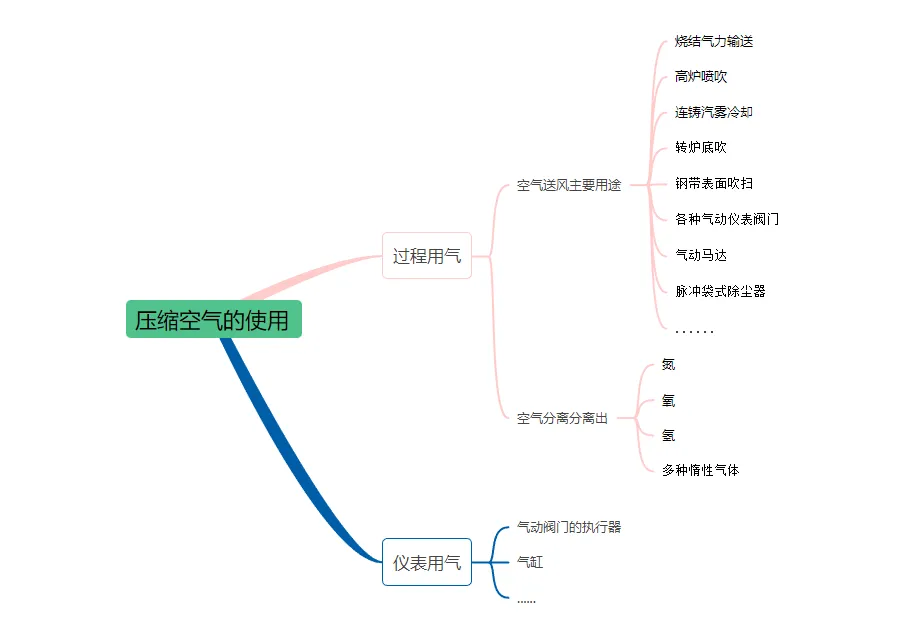

在钢铁企业中压缩空气的使用包含在各个生产环节之中,主要分为:过程用气和仪表用气。

上述用气方式, 均对压缩空气的品质(颗粒物、湿度、残余油)有一定的要求。 而一台合格的吸附式压缩空气干燥机可确保压缩空气(PDP)≤-20℃乃至更低,对于降低压缩空气中的湿度起到决定性的作用。

因此,吸附式压缩空气干燥机在钢铁企业的生产过程中起到非常重要的作用。以下是吸附式干燥机在钢厂中的作用:

01防止生产设备腐蚀

钢铁生产过程中,生产设备经常暴露在湿度较高的环境中,容易受到腐蚀。吸附式压缩空气干燥机可以有效降低压缩空气中的湿度,减少设备腐蚀的风险。

02提高钢铁产品质量

在钢铁制造中,压缩空气湿度对产品质量有很大影响。湿度过高可能导致产品表面出现氧化、锈蚀等问题。通过使用吸附式压缩空气干燥机,可以确保生产过程中使用的压缩空气干燥,提高产品质量。

03增加生产效率

吸附式压缩空气干燥机能够快速降低压缩空气中的湿度,防止生产中出现与湿度相关的问题。可以提高生产效率,避免因为湿度问题导致的生产中断。

04延长设备寿命

湿度对生产设备的影响不可忽视。过高的湿度可能导致设备内部零部件腐蚀,降低设备寿命。通过使用吸附式压缩空气干燥机,可以减轻设备的腐蚀程度,延长设备的使用寿命。

05提高安全性

在一些钢铁生产过程中,压缩空气中的水分可能与某些化学物质反应,产生危险气体。通过保持压缩空气干燥,可以减少这类危险气体的产生,提高生产过程的安全性。

02/与国内钢厂项目合作

武钢集团是新中国成立后兴建的第一家特大型钢铁联合企业,于1955年开始建设,1958年9月13日建成投产,是中央和国务院国资委直管的国有重要骨干企业。

自上世纪90年代初,日盛就与武钢展开合作,陆续提供了多台套、多种规格的压缩空气干燥机。

2016年起,结合武钢对于空压站设备节能改造的需求, 日盛又陆续向武钢提供了数十台大型零气耗压缩空气吸附式干燥机 , 设备的品质和节能效益都得到了武钢用户的一致好评。

马鞍山钢铁股份有限公司是我国特大型钢铁联合企业之一,安徽省最大的工业企业之一。马钢有铁、钢材1600万吨配套生产规模,总资产近900亿元。

2020年起,日盛又与马钢合作,并提供多台大型零气耗吸附式干燥机。现场运行测试完全满足用户的技术要求,并为马钢带来了丰厚的节能效益。

03/与国外钢厂项目合作

俄罗斯钢管生产商联合冶金公司OMK是俄罗斯的骨干企业,其集团旗下的子公司Vyksa Steel目前是俄罗斯焊管生产的主力军,也是俄罗斯历史最悠久的黑色治金企业之一。在与 Vyksa钢厂的合作中,日盛工业为其量身定制了两台超大型零气耗吸附式干燥机设备。鉴于日盛公司技术方案中突出的节能特点、优异的结构设计, 以及在运东市场的良好口碑,客户未到场验货就同意出货,充分体现出了对日盛工业的产品工艺和品质的满意和信赖。

该项目为两套大型鼓风吸附式干燥机RSXB-4500ZP和前后端过滤器,用于钢厂设备防腐除湿,延长设备寿命。在此项目中,鼓风吸干机非标要求较多,非常考验制造工艺、技术水平和设计能力。

日盛致力于压缩空气干燥机三十余年,为客户提供了无数次满意的产品和设计方案,以高品质和高要求赢得客户的信赖。此次项目也不例外,前期与客户沟通项目内容,满足客户需求,后期与技术部等讨论设计方案,圆满完成了此次项目。该项目不仅展现了日盛工业在制造大型设备方面的高超技艺,更是日盛对品质的承诺。每一个零部件,每一道工序,都经过严格把控,确保设备的稳定性和高效性。日盛提供的产品不仅仅是机器,更是对客户负责的态度。

团结 | 合作 | 共进

- END